Does your organisation have a viral outbreak maintenance or decontamination plan?

Jaymak can help.

As certified cleaning professionals, we’re here to help you develop and implement a response suited to your business’ needs. Just give us a call on 1300 529 625 or email sales@jaymak.com.au.

For a number of years Jaymak has partnered with a leading practitioner in viral decontamination cleans of facilities – Biosafety who brought the ClorDiSys chlorine dioxide gas decontamination process from the USA to Australia.

Jaymak’s partnership with Biosafety provides a cost-effective chlorine dioxide liquid disinfectant maintenance and decontamination processes for the eradication of yeasts, moulds and viruses (including Coronavirus) which includes:

- A fixed full day rate regardless of the number of rooms or weekend/weekday work

- Supply of equipment and consumables to decontaminate each area

- sealing of vents, doorways and other building facilities as required (to be confirmed upon site evaluation)

- ULV Fogging/Misting System for the delivery of chlorine dioxide liquid aersolisation (2-5 micron aersolisation)

- ATP Testing as standard validation included (particle count validation options)

- A fully documented report by an independent Occupational Hygienist to certify and validate that the treatment has effectively killed the Coronavirus.

As well as killing Coronavirus, electrostatic fogging with chlorine dioxide as a liquid disinfectant can also kill many other yeasts, moulds and viruses. The treatment also provides up to a 5-log reduction in microbial and pathogen load or a lowering in the number of microorganisms by 100,000-fold.

This process delivers a disinfection service which is similar to healthcare cleaning processes which we regularly use in the food and beverage industry to maintain superior hygiene standards (5-log pathogen reduction performance standard).

Protect your team, your business and your customers from viruses, bacteria, spores, and other harmful organisms.

As certified and experienced cleaning professionals, we’re here to help you. Just give us a call on 1300 529 625 or email sales@jaymak.com.au.

What is chlorine dioxide?

Chlorine dioxide (ClO2) is a yellow-green gas however it can also be used as a liquid. It has been safely used for more than 70 years to disinfect food and water supplies and is also widely used at water treatment facilities globally. Chlorine dioxide has the advantage that it produces fewer harmful by-products than chlorine.

Chlorine dioxide gas has been used to sterilize medical and laboratory equipment, surfaces, rooms and tools.

Chlorine dioxide can be used as an oxidizer or disinfectant. It is a very strong oxidizer and it effectively kills pathogenic micro-organisms such as fungi, bacteria and viruses including Coronaviruses. Chlorine dioxide does not react with ammonia or most organic compounds, it oxidizes products rather than chlorinating them, so unlike chlorine, chlorine dioxide will not produce environmentally undesirable organic compounds containing chlorine.

Is chlorine dioxide safe?

Chlorine dioxide is toxic, therefore limits on exposure to it are needed to ensure its safe use and the correct Personal Protective Equipment (PPE) and safe operating procedures must be followed. Additionally, not all products on the market that produce chlorine dioxide are the same and the acidic by-products generated by most methods can cause harm to equipment and surfaces.

The Jaymak/Biosafety partnership for our chlorine dioxide fogging service gives you the comfort to know we can provide the necessary operational, TGA and food safety documentation and create a neutral solution that won’t cause any harm or damage to equipment or surfaces.

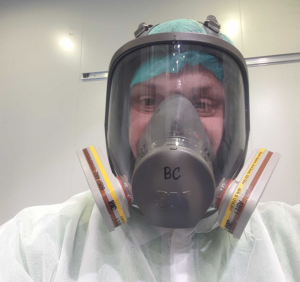

During application, PPE such as a full-face respirator or PAPR[1] is worn by all people present. Safe concentrations are verified prior to re-entry without PPE – usually within minutes.

The chlorine dioxide that we use as a liquid disinfectant is safe on materials and leaves no post treatment residuals, making it safe to use in the most critical environments.

We have experience. We have offered this service and completed treatments in food processing and manufacturing facilities for the successful and safe eradication of outbreaks such as yeast, mould and listeria – even before the occurrence of COVID-19.

Why is fogging with chlorine dioxide better than normal disinfecting?

Cleaning reduces soil load and biofilm which is an essential part of disinfecting.

However, regardless of how well you clean, it is nearly impossible to remove all microbial loads from surfaces and in the air.

As an additional treatment to traditional physical cleaning and disinfecting methods, a facility can be fogged to provide whole room decontamination, including hard to reach areas through opening drawers, cabinets and enclosures, as well as changing the angle of application in order to maximise contact areas. Fogging also minimises the need to use ladders and access equipment to disinfect elevated furniture and equipment.

Fogging with chlorine dioxide as a liquid disinfectant is effective against a wide range of viruses, bacteria, fungi and spores.

Handheld fog generators are used by technicians to produce fine mists, in significant quantities for maximum impact. High concentrations of fine fog remain in the air to give effective disinfection times. Fogging with chlorine dioxide as a liquid disinfectant is very effective at microbial control.

Fogging is effective for maintenance and decontamination of Coronavirus across[2]:

· hospitality and food services

· medical and health care including hospitals, aged care and medical centres

· educational institutions such as schools and universities

· sporting and community clubs and gyms

Coronavirus in the Workplace[3]

A study[4] by National Institutes of Health, CDC, UCLA and Princeton University scientists found that severe acute respiratory syndrome coronavirus 2 (SARS-CoV-2) was detectable in aerosols for up to three hours, up to four hours on copper, up to 24 hours on cardboard, and up to three days on plastic and stainless steel.

The results provide key information about the stability of SARS-CoV-2, which causes coronavirus disease 2019 (COVID-19), suggesting people may acquire the virus through the air and after touching contaminated objects.

This is one of the factors that makes this COVID-19 virus so highly contagious.

Further, some global areas now have ongoing community spread with the virus that causes COVID-19. Community spread means people have been infected, and it is not known how or where they became exposed. There have been a number of instances of community spread recorded in Australia as well.

The presence of coronavirus within an organisation can be effectively eradicated by high-level disinfection services in a facility’s high traffic areas.

The Top 10 Things you need to know about our Fogging Service if there is a suspected or confirmed case of COVID-19

1. What is the lead time or protocol for Jaymak’s fogging services?

Jaymak/Biosafety are prioritising all disinfectant fogging work for COVID-19 with any non-essential fogging on hold until further notice.

If there is a suspected or confirmed case of COVID-19 at a site that requires decontamination, please ring us immediately. We can then coordinate the deployment of Jaymak and Biosafety personnel to assist with the emergency response plan. Sites in Victoria we would be able to respond within 12 hours. Outside of Victoria is between 24-48 hours depending upon location.

2. What do I need to do to prepare for a fogging service?

Cleaning is an essential part of disinfecting and the significant amount of organic load and biofilm in many of facilities can inactivate the disinfectant or reduce its effectiveness. Cleaning reduces the soil load, allowing the disinfectant to work as it is designed.

In many food production and manufacturing facilities, the evaporator coils need to be inspected and cleaned first before they can be fogged with disinfectant. So that businesses are ready for fogging once the COVID-19 situation has been brought under control, please make contact with us so that these can be completed as a priority.

3. Does the site need to provide any specific equipment or personnel?

No. All equipment, service technicians and supervision are provided and managed by us in conjunction with Biosafety.

4. Can we leave food open in the facility or can people be present when you are fogging?

No – Chlorine dioxide is toxic, therefore limits on exposure to it are needed to ensure its safe use and the correct Personal Protective Equipment (PPE) and safe operating procedures must be followed.

All open food should be removed from the site if possible or securely covered and protected.

5. Do you need to review our site map?

Yes – site maps are required and will need to be provided to us prior to commencement of the work

6. What about flight issues and compulsory isolation if I’m interstate?

If there is a confirmed or suspected case of COVID-19 that needs decontamination in Victoria, NSW or QLD, Biosafety and Jaymak personnel are deemed an ‘essential service’ under the state legislation Essential Services Act.

Once cleared with the respective authorities, our team should be able to mobilise without the need for compulsory isolation.

In other states and territories, we are still yet to receive clear notification of our ‘status’. Please contact us on 1300 529 625 to discuss your needs.

7. When is the service usually carried out?

The disinfectant or decontamination process is normally performed over a weekend period to minimise the disruption to business operations. However, Jaymak can schedule work around your business’s needs.

The site must be vacant during the service and that all air conditioning units and fans be shut off until the space is reoccupied.

8. How soon can a space be safely used after an electrostatic fogging disinfecting service?

Where the process is carried out on a weekend, the facility would be available for normal operation on the Monday morning.

Safe concentrations are verified prior to re-entry without PPE. In most cases, only minutes are required to get below 0.1 ppm prior to re-entry.

It is possible for spaces to be available within hours of the service completion.

There may be a slight sweet chlorine smell for about 24 hours after the service, but this is not an occupational hazard and is perfectly safe for occupancy.

9.How long does the service last on the treated areas?

The service lasts throughout the chemical dwell time and as long as the space is not reinfected with bacteria and/or viruses.

If you suspect a space becomes reinfected, then we recommend an immediate follow-up electrostatic fogging service.

10. How often should the service be conducted?

Electrostatic fogging services can be conducted as often as required by the site and situation. Medical facilities typically require more frequent services, and during peak flu seasons sensitive facilities such as education centres, sports facilities etc. tend to increase their service frequency as well to maintain hygiene status.

SOURCES & REFERENCES:

http://blog.clordisys.com/2019/04/if-your-facility-does-not-necessarily.html

https://www.clordisys.com/index.php

https://www.nih.gov/news-events/news-releases/new-coronavirus-stable-hours-surfaces

https://www.viruscontrol.com.au

[1] a battery-powered blower that provides positive airflow through a filter, cartridge, or canister to a hood or face piece

[2] https://www.clordisys.com/index.php

[3] http://blog.clordisys.com/

[4] https://www.nih.gov/news-events/news-releases/new-coronavirus-stable-hours-surfaces

Comments are closed.